|

1951 Vintage Crush 10,692 tons

Allocation was 2,828 tons to Wine and 7,864 tons to Spirit, 26.45%

Average Baume 13.8°

I commenced in February in the 1951 vintage and I remember the winery complex being very large and seemed to stretch in all directions along the Sturt Highway. In the next two years I was given experience in all sections of the plant. My starting weekly wage, at the junior clerk rate, was three pounds five shillings and sixpence. Board at home was thirty shillings, one pound towards the Roseworthy course and the rest I splurged on teenage activities.

In 1951 there were three methods of qualification for the Oenology course. The first was to obtain a Diploma in Agriculture at Roseworthy over three years, the second was to study for the first and second years of Agriculture, and then two years of Oenology, and thirdly to complete two years employed in the wine industry and then study Oenology for two years. The latter suited my situation and to qualify I had to study the extra required subjects of Soil Science and Biology which my Leaving studies had not addressed. This I did, and was successful in the exam and was granted entry to the course commencing May 1953. This gave me a chance to save money and provide clothing and essential items for the years 1953-54. My father had decided to fund the course fees for two years and I would be responsible for the incidentals. From memory the annual fee was £110 per year for tuition and board and laboratory breakages were additional charges. From memory, I believe £2-15-9 was my damage account for breakages of laboratory glassware during the course.

I have decided to start in 1951 having researched to that year. It may be out of order, but I consider it important to see how the vintage was processed after the large expansion of the premises that took place after the 1947 vintage.

Vintage in 1951 was processed in three cellars.

No.1 Ferment Cellar

This cellar was situated immediately south of the Block 1 roadside tanks H.M.C. 101-112 positioned along Sturt Highway opposite the Karoom railway siding.

This Cellar was serviced by four Whitehill crusher/destemmers. No’s 1 and 2 crushers were 20 ton per hour capacity and each had a receival bin and No's 3 and 4 crushers were 30 ton per hour were fed by twin bins. Whitehill vertical must pumps delivered the must to the concrete open topped tanks inside the cellar using a network of 4 inch (100 mm) diameter pipelines and flexible hoses. The stalks were elevated from each crusher discharge to a flume supplied with circulating liquid that washed the stalks to a draining screen and elevator at the east end of the building. I understand the grape receival bins were constructed with segments of reject steel armour plate from World War 2. Because of the bin construction there were many blockages caused by the bridging of the bunches above the auger and I became expert at relieving the hold-up with a 3 meter long pole of mallee timber. Grape juice corrosion also took a toll of the metal bearings and we eventually installed red-gum bearings that would last the season given that regular grease was applied several times a day.

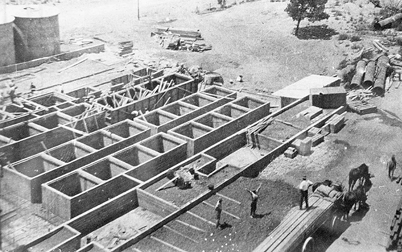

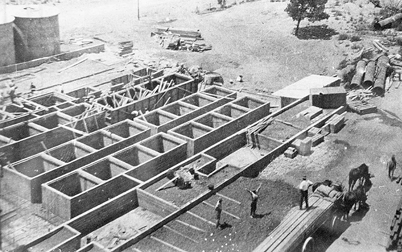

The Cellar was laid out with 120 open top tanks, all of the same dimension and each held 1500 gallons, and the cellar operated as mirror images east and west. 80 tanks. The west end section was built after the 1923 vintage , 40 each side were used to receive the crushed destemmed grapes and would each hold 7.5 tons at 200 gallons per ton. These were known as Skin tanks. The other 40 tanks, 20 each side were used to receive the runoff fermenting juice from the Skin tanks. Known as the Runoff Tanks.

|

Looking east of north east. This photo shows the east end Skin Tanks under construction.

.

|

Two drains serviced each pair of tank rows and the sloping drains fed to sumps feeding open impeller centrifugal pumps that could deliver grape juice to the Runoff tanks as well as Block 1, 3, 4, 5, 6 and 7 tanks via 75 mm diameter copper pipelines.

Runoff Tanks

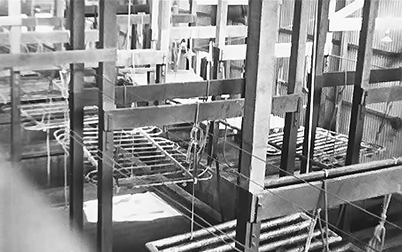

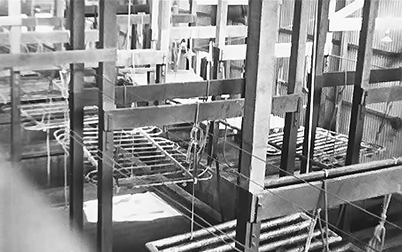

These were again open top tanks and held 1500 gallons of fermenting grape juice and were on the Sturt Highway side of the cellar. There were two rows of 10 tanks at both the west and east end of the cellar with a common drain at each end of the cellar. These tanks were fitted with copper cooling coils through which cold water passed and maintained the temperature to a desired level. The warm discharge water was then sprayed onto the cellar roof through sprinklers and the evaporative effect reduced the temperature and the cooled water was returned to the cooling process. This cooling system was fitted to the East end Run-Off tanks and had flexible hoses to allow the tube panels to be raised and lowered.

|

You

can see in this photo, some of the panels are 1" diameter

copper tube and others panels are 11/2 inch diameter.

|

Two drains serviced each pair of tanks and the sloping drain fed to sumps feeding open impeller centrifugal pumps that could deliver product to Block 1, 3, 4, 5, 6 and 7 tanks via 75 mm diameter copper pipelines and flexible rubber hoses.

There was also a connection at each end of the cellar to deliver the drained marc to the Tarac facility . This was done by Tarac supplying fermented wash to sludge the skins and seeds to their holding tanks where the fermentation of the remaining sugar was completed. Tarac would separate the wash from the skins and seeds and depending on the quantity needed for sludging the next day, the excess fermented wash was distilled to produce “low wines” spirit that was delivered back to our distillation section to be rectified into high strength spirit for the production fortified sweet wines, usually with a Baume of 4.5° and an alcohol content of 34% Proof Spirit. Refer to Tarac process.

To the east of No.1 Cellar there were 21 tanks of tanks of 20,000 gallon capacity that were used for fermentation of wine to be distilled for either brandy or fortifying spirit. Tank numbers were H.M.C. 120-124, 130-134, 140-144 and 150-155. I should explain that all of the wine tanks were recorded with the H.M.C. (His or Her Majesty's Customs) prefix as required by Customs and Excise.

A timber frame ladder and rickety walkways with steel pipe handrails that wobbled and swayed according to personal weight and velocity. Block 1 H.M.C. Tanks 101-111 (Flat-top) Sturt Highway roadside. Capacity each 20,000 gallons or 90,000 litres. Tank 112 (Conical top) 21,000 gallons or 94,500 litres.

All of these tanks were of reinforced concrete construction with an inner and outer plaster coat. A melted wax coating protected the internal surfaces of the tanks. I believe that all of the concrete tanks were built using four foot (1200 mm) high cylindrical formwork and the courses was poured in stages and there was an eventual loss of integrity at each joint. Explain the consequences when I had returned from Loxton.

When the fermentation was completed the wine would be pumped across to the wine chargers and there would be tested for alcohol content and the volume measured, then details entered into the Notice Book, and could then be directed to the stills. Both the Company and the Excise Staff kept matching records.

No. 2 Ferment Cellar

Situated on the northeast corner of the land this cellar had two grape receival bins feeding a rated 40 ton per hour Whitehill crusher. A similar water flume system to that in No.1 Cellar, was used to remove the stalks from the east end of the building.

A vertical Whitehill must pump delivered the must to twenty-four (four rows of six tanks) open top concrete skin-tanks each holding 14 tons. Capacity was 336 tons of grapes. Across the cellar at the west end were four run-of tanks. Four side drains serviced the four rows of tanks leading to a sump equipped with an open impeller centrifugal pump. This could deliver product to tanks in all Blocks except Block 2. Research is ongoing and there were 28 tanks in the building-refer to notes from Bob Rowe, Ian McKenzie, Bill Wilden etc.

No.3 Ferment Cellar

This was the original grape receival cellar west of the present boilers and abutted to the Stillhouse complex. In my time this cellar could receive grapes from No. 3 Crusher when space was at a premium. Probably half of the tanks were used to store distillation material and three tanks were used as Wine Chargers, namely W/C's 13,14 and 15 in the south east section of the Cellar.

In 1951, to the west of the still-house, were two concrete structures of containing a number of tanks. Just like a loaf of bread they were called the Sugarloaf's. The eastern tanks were known as Wine Chargers 1 to 5 and the western tanks Wine Chargers 16 to 19. I assume from a photograph of the extension of the No.3 Cellar after the 1922 vintage, these were built for the 1923 vintage as wine charge tanks, to supply the stills. On the south side of the western block four 20,000 gallon tanks were built and were known as Wine Chargers 6 to 9. Earlier in the story I have presumed when these tanks were built and may be somebody can put the record straight.

I can still remember the north wall of No. 3 Cellar faced in corrugated iron with two openings through which the grapes were forked or shoveled and one opening still had remnants of hessian hanging by threads. This hessian supposedly covered the opening to stop ingress of flies etc.

The grape crushers were long gone, but the concrete must pits with crusher and must pump holding down bolts were still there.

This cellar was laid out with three rows of tanks, the two northern rows were used as skin-tanks and the southern row had six tanks, the south-west three were for distillation material and the south-east tanks were Wine Chargers 13, 14 and 15.

The skin-tanks could hold 468 tons of grapes, but this cellar was only used when space was a problem in No.1 and 2. Cellars when the harvest was at peak levels. Most of the time 50% of the skin-tanks were used to hold fermenting wine, lees wine and storage of distillation wine.

Two drains delivered to a sump fitted with a Pomona type centrifugal pump. Ideal for pumping high solids liquid. Grape must was delivered to these tanks via No. 3 crusher must pump through an overhead 100 mm diameter pipeline. In my time we used a 4" diameter "Pope" galvanised pipeline that had been internally coated with hot wax. Trucks in a hurry after discharging the load of grapes with the tip-tray still in the upright position often brought this pipeline down. |